INTRODUCTION

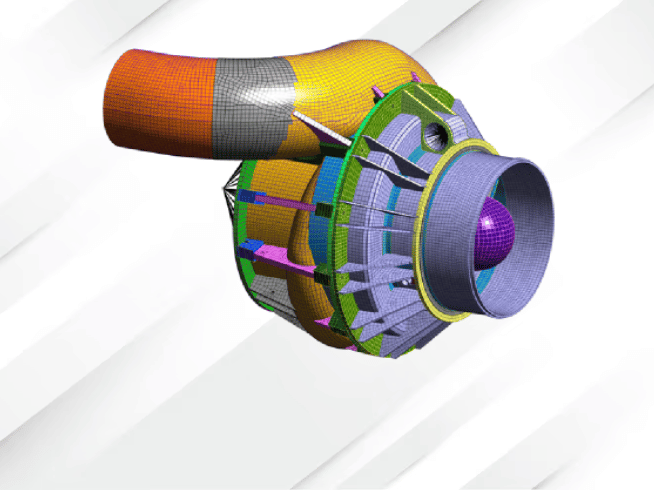

Finite Element Analysis (FEA) has become a highly beneficial technique in the field of computer-aided engineering & design, in particular for the modeling and analysis of structures with complicated geometries and non-linear material properties. It is now being widely used at the early stages of design within various engineering domains, including automotive, aerospace, power plants, production, and process industries, for product optimization that improves performance and reduces the cost of components.

Components that are subjected to thermal and structural loads can be evaluated with the FEA technique for structural reactions caused and their reliability under such load conditions without need to create the actual component. It validates design integrity and pinpoints critical spots in a component subjected to various structural and thermal loads. FEA has evolved as a cost effective technique that helps to design engineers create optimal and reliable components and systems that would aptly fit the applications at a very low cost, with a significant reduction in time required for such a development process through traditional methodologies. It also helps businesses accelerate the development of new products in a very cost-effective manner with a shorter lead time, thereby keeping them ahead of their competitors in the market.

FEA Capabilities

- Nonlinear Analysis

- Static Analysis

- Dynamic Analysis

- Thermal Analysis

- Buckling Analysis

- Fatigue Analysis

Linear Analysis

Finite Element Analysis, commonly employs linear statistical analysis as the primary method of analysis to assess the structural members subjected to simple mechanical and thermal loads. Linear static analysis can accurately capture the relationship between applied forces and displacements for structural problems within the linear elastic range of the material. In such an analysis, the stiffness matrix of the model is constant, resulting in relatively short solving times compared to a nonlinear analysis. Therefore, a linear static analysis is often used as an initial estimate instead of performing a complete nonlinear analysis for assessing the structural members subjected to larger deformations.

Non-Linear Analysis

Non-linear analysis is a time dependent problem. The analysis is said to be nonlinear if the connection between the applied forces and displacements is nonlinear. Material non linearity (elasto-plastic material) and geometric non linearity (large deformations) can all result in nonlinear effects. The stiffness matrix changes as the load is applied as a result of these factors. In contrast, linear static analysis’s stiffness matrix remained constant. As a result, nonlinear analysis requires the use of a different solving strategy and, therefore, solving time and computational requirements increase when compared to linear analysis.

Static Analysis

Using the FE approach, static stress analysis is the most commonly used kind of structural analysis. To prevent major failures at the design & operation stages, stress, strain, and deformation of a component or assembly can be evaluated under different load conditions.

Structural loads often include one or more of the following, or a combination of them

- External forces such as clamping forces in subsea connectors

- Surface loads, e.g., pressure loading in pressure vessels

- Body forces (gravity, acceleration, such as centrifugal force in rotating machines)

- The multi-physics methodologies available within the FEA technique allow for the simulation of the structural response to more complex load conditions, such as thermo mechanical stress analysis and vibro acoustic analysis etc

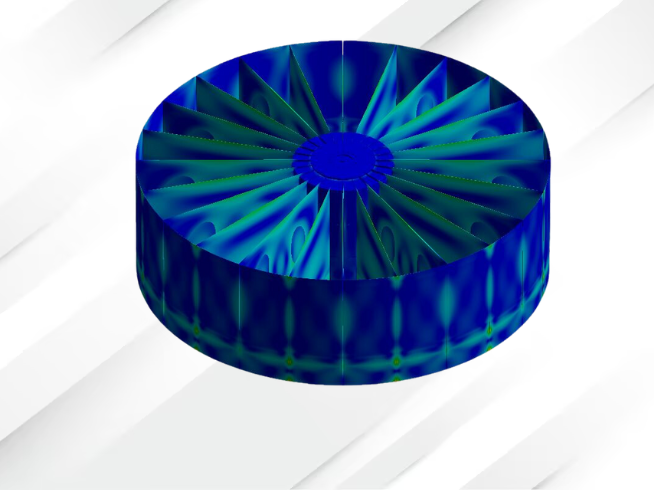

Dynamic Analysis

Dynamic analysis refers to transient state simulation i.e. system or element when subjected to time varying loads and resulting stress factors. It adopts more complex algorithms compared to static analysis, along with a significant increase in solving time and computational requirements.

Vibration analysis, an example of Dynamic analysis, is a branch within FEA that helps to assess the vibration characteristics of a system and its structural members when subjected to both internal and external load conditions. Structural Vibration being an important phenomenon that needs engineers attention at the early stages of design, it can impose major challenges in the product development process and also during its regular operation since vibration could result in catastrophic damages to both the system and humans.

Testing for vibration analysis is expensive. Performing dynamics analysis (Vibration analysis) during the design phase can help to avoid or minimize the need for and expense associated with rig testing.

Under dynamic loads, failures might have severe consequences. You can prevent making expensive mistakes by taking into account performing dynamic analysis during the design phase.

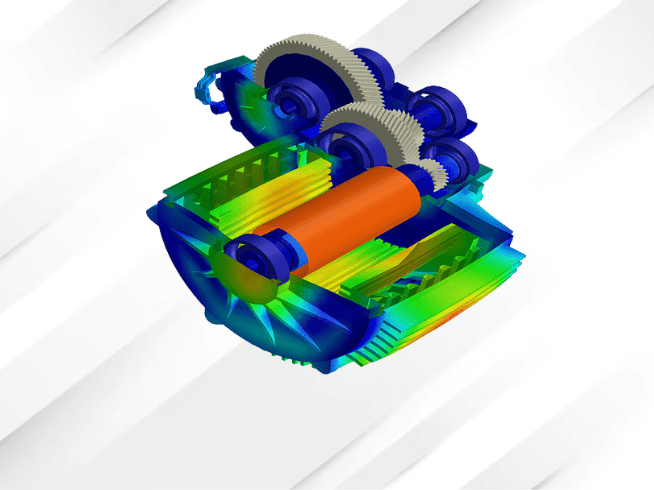

Thermal Analysis

Solving the heat transfer in or between solids using FEA is possible through the use of the thermal analysis module. Calculations can be made for heat transmission processes such as convection, conduction, and thermal radiation. However, the analyst must explicitly identify convection and thermal radiation; the FEA software does not do these calculations.

When the heat convection coefficient can be considered to be constant over the surface of the part or if the value is accurately known, heat transfer analysis with FEA is typically performed.

Thermal expansion and structural stresses resulting from thermal gradients in the part can be predicted using heat transfer analysis.

The stability of a structure under compressive loading circumstances is assessed via buckling analysis. To test the structural stability of a weight-lifting system under compressible loads, buckling analysis will be required.

First, a linear buckling analysis must be performed then followed by a static structural analysis. Buckling load factors- the outputs of a linear buckling will be used in the static structural analysis, implies, when the threshold limits of static loading are reached, the structure will experience buckling failure. There are countless buckling load factors for a structure. Similar to modal analysis, every load factor has a unique instability pattern connected with it. However, the lowest load factor is of interest in most of the scenarios.

A series of buckling analyses will be required to determine the limit of the external loads. There are several loads, some of which are constant (self-weight) and others of which are variable (externally applied loads).

Shape displays in Buckling Mode Analysis provide useful details for comprehending how the structure deforms during buckling. If necessary, this information will serve as a guide for strengthening the structural or load bearing members.

Fatigue Analysis

Instead of simulating one load cycle as in a static analysis, a fatigue analysis helps in determining whether a structure would fail after a specific number of repeated loading and unloading or during a cyclic load. Cracking is the usual phenomenon by which a structural member subjected to Fatigue loading will fail.

A stress analysis is always required prior to a fatigue study. Either a static stress analysis (which will provide a single peak stress) or a random vibration analysis (RVA), which will produce several peak stresses.Stress must be lowered to a single stress value if an RVA is performed.

Advantages of FEA

- Minimize the product development cost

- Reduce the product lead time into market

- Precisely forecast how components will behave under load

- The system’s infinite level of detail

- Analyze difficult and dangerous experiments

- easy repeatability of simulation