INTRODUCTION

The new generation seals named TALCON (TEFUGEN Automatic Leakage Control) are highly effective radial seals for Rotary Air-Preheater (RAPH) which has a unique design to significantly reduce the clearance between the sector plate and diaphragm plate occurring due to turndown during APH operation. This reduces the direct leakage of air into flue gas side of RAPH.

Conventional Radial Seals

The in-board, intermediate, and out-board radial seals in the conventional RAPH design are attached directly with the diaphragm plate along its entire length. During APH operation, turndown occurs in the rotor and hence the conventional radial seals attached with the diaphragm plate moves along with the diaphragm plate which increases the leakage gap formed between the sector plate and diaphragm plate.

New Radial Seals: TALCON TM

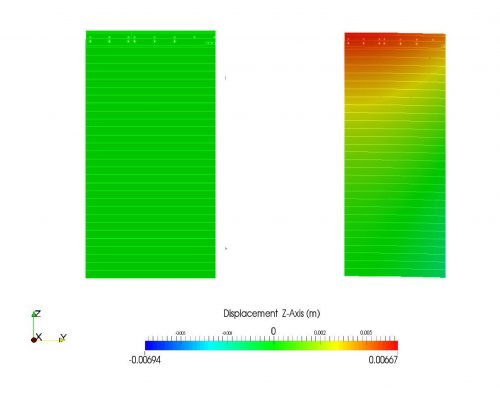

The bolt configuration of the seal mount at the inboard end is determined using Finite Element Analysis (FEA) and plays a pivotal role in the effective working of radial seals. During APH operation, the working temperature at the hot end activates the bi-metallic strip, which in turn lifts the seal mount to an extent equivalent to that of the rotor turn-down. This in turn reduces the leakage gap significantly as compared to the conventional design, thereby reducing the direct leakage of air into the flue gas side.

CONSTRUCTION

The new radial seal design comprises the following components as depicted in Fig (I);

1) Seal Stiffener 2) Seals 3) Side Support 4) Guide Angle

Unlike the conventional design, radial seals in this new design are attached with a “Seal Mount” instead of a diaphragm plate. The seal mount is bolted with the diaphragm plate only at the inboard end, whereas the remaining portion of the seal mount is allowed to slide freely over the diaphragm plate like a cantilever beam. A “bi-metallic strip” is attached to the lower portion of the seal mount at the inboard end. The bi-metallic strip is attached such that during APH operation, it lifts the seal mount to the designed value at the outboard end. “Lateral Guides” are provided at regular intervals to prevent the outward movement (holding the seal mount to the diaphragm plate) of the seal mount during operation. A “Protector Angle” arrangement is provided at the outboard end, which restricts any excessive upward movement of the seal mount and thus prevents it from interfering with the sector plate.

FEA Results

The below graph was predicted using FEA and represents the turn-down pattern of TALCONTM seals (green) plotted against the existing radial seals (brown). A prototype of the TALCONTM seals was manufactured and tested in the furnace, simulating the actual APH operating conditions. The test results were used to successfully validate the FEA model.

Leakage results of TALCONTM seals (for typical APH sizes) obtained from the combination of FEA and physical testing are displayed in the table below.

| Hot-End Leakage with TALCONTM Seals (for typical APH size) |

| Leakage Area with conventional Hot-end Radial Seals | 50,000 (mm2) |

| Leakage Area with TALCONTM New Seals | 12,500 (mm2) |

| % Reduction in Leakage | 75.00% |

Benefits of TALCON TM

- Increase in efficiency of RAPH

- Reduction in auxiliary power consumption

- Reduction in drift loss

- Reduced cost and reduced maintenance

Conclusion

The combination of Test and FEA results indicate that a reduction of around “75% hot-end radial leakage” and “25% total leakage” can be anticipated by the implementation of TALCONTM seals as compared to conventional radial seals.