Introduction

Process industries like chemical, ceramics, food, and metal processing require the ongoing use of affordable and dependable procedures for productivity growth, cost cutting, and energy consumption reduction. Applications of CFD in the process industry demand that the flow be addressed in complex geometries and with complex physics. CFD offers a very valuable and in-depth understanding of diverse processes and the operation of complex equipment in a short amount of time and at a lower cost thanks to expanded capabilities and tested flow models. It has proven to be a very practical and efficient instrument for enhancing the performance of existing equipment or designing new equipment more efficiently. Process industries employ CFD for a variety of tasks, such as the study and improvement of rotating kilns, particle separators, mixers, mixing systems, nozzles, injectors, extruders, chemical processing equipment, and food processing equipment.

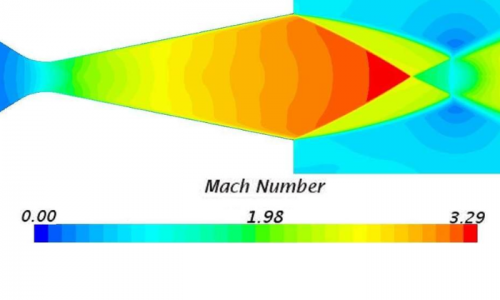

Nozzles and Injectors

In order to select the best alternative designs for marginal improvements objected to in the design of nozzles, turbines, injection systems, and their elements, precise procedures are needed. The position of eddies, pressure gradients, shocks, velocity distribution, stream line curvature, and streamwise vortices are all determined using the CFD technique since it has intrinsic advantages over other simulation methods.

Our expertise in these areas could assist you with

- Optimization of air and fuel injecting systems within burners

- Optimization of nozzles and injectors

- Performance assessment of injection systems and injectors

- Steam injection system modelling and analysis

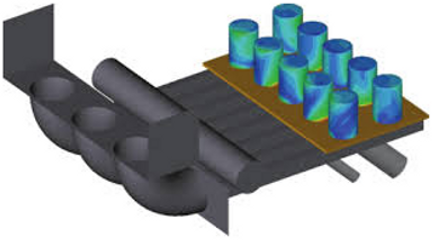

Quench Tank

The design and performance of the systems and related equipment in heat treatment plants and processes must be continually improved. Because quenching is one of the most important, time-consuming, and energy-intensive processes in a heat treatment cycle, it requires ongoing development for heat treatment plants to operate efficiently. Part Quality, Heat Transfer Rate, Effective Nozzles and Injecting System, Flow Distribution, Cooling Time Required, and Optimal Tank Size are the main factors connected with Quench Tank Performance Improvement. These parameters could be acquired or assessed at an early stage with the use of CFD. Additionally, it has the benefit of requiring less experimental work, expense, and lead time to estimate the agitation process and evaluate quench tank performance.

Our expertise in these areas could assist you with

- Flow pattern and temperature distribution assessment

- Heat transfer and cooling rate prediction

- Process optimisation of quenching tanks

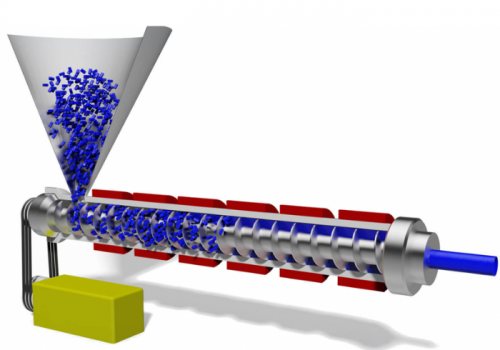

Extrusion

Designing extruder components, particularly the dies and screw shafts that experience high wear, is a significant difficulty in the extrusion process used in the polymer and ceramics industries.

flow models are ideally suited to handle such flows. Even for geometries with complex forms, it gives fluid velocity, pressure, and temperature measurements across the domains. To create an optimum component design, parametric design studies could be carried out easily and affordabl.

Our expertise in these areas could assist you with

- Performance assessment of extruders

- Optimization of die design